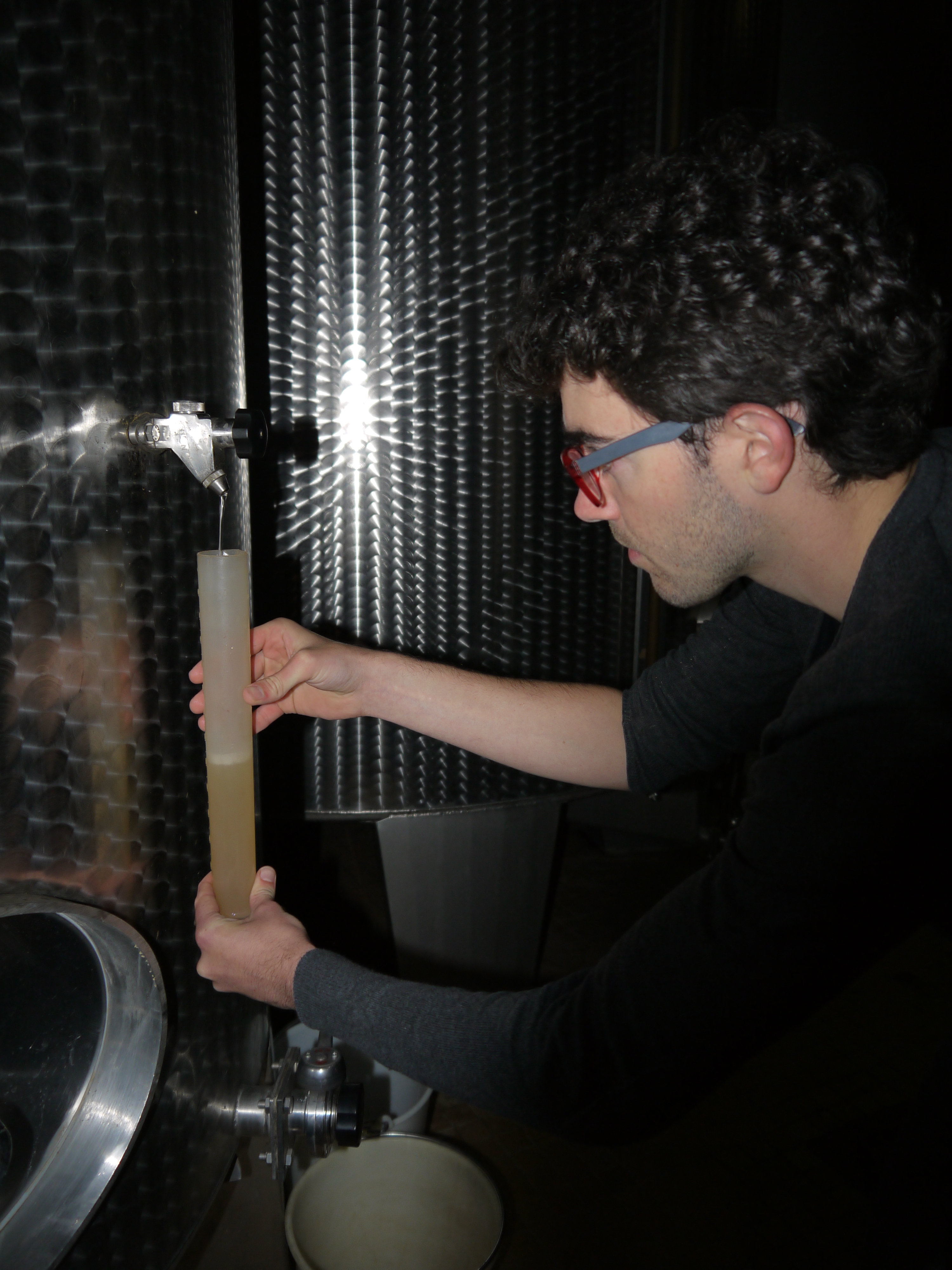

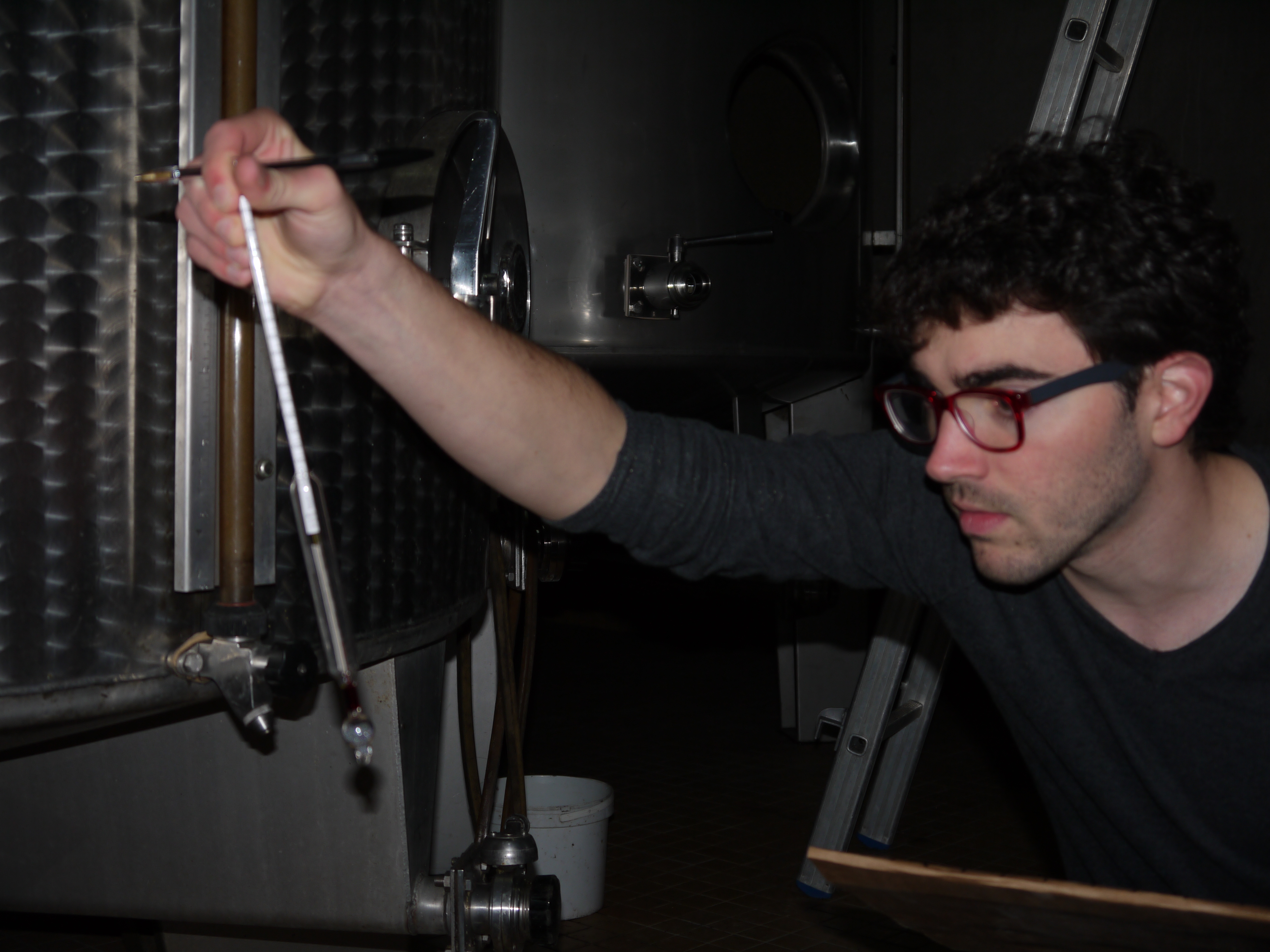

Our philosophy in terms of wine making process of pouilly fume is to privilege physical treatments in order to banish the chemical ones (even the softest) and to use the less SO2 as possible.

That is why we work with three main principles : the use of gravity, the use of cold settling and the keeping of the fermentation CO2.

Our cellar is built on three levels, two of them are buried. On the ground floor the grapes are collected and squeezed by three pneumatic presses. The juices selected go down, without any pumping, to the -1 level in stainless steel tanks where they are must settled thank to the cold settling. The clear juices are then dispatched to the -2 level stainless steel tanks which are equipped with devices allowing us to control fermentation temperatures tank by tank (because we banish uniformity).

The wines are kept on fine lees at controlled temperature. Tartric stabilisations are made by maintaining the wine at a negative temperature for 8 days, at the ground floor. Bottling is carried out at -2 level. At this level, optimal conditions allow the storage in bottles and the ageing of some of our cuvées.

Our wish is to equip ourselves with the most reliable means as well as privileging human intervention, which is the only responsible for “the soul of the wine”. We put a lot of ourselves in the culture of our vines and in the vinification of our Pouilly-Fumés in order to personalise our products to the maximum. This does not impede us to secure the whole wine making process, so an oenologist from the SICAVAC monitors our harvest with us (from the maturity sampling in order to determine the optimal date for harvest. He comes every two days in the cellar together with the result of the daily analysis of the musts and finally with the complete analysis of the whole finished wines.

In the same way, we invested in a bottling line equipped with a retention chain in which the bottles are moving along during 7 minutes before being piled up (this allows the cork to loosen and stick perfectly to the glass to avoid the leaking problems). The total control of bottling allows us to carry it out ourselves at the right time – chosen by us- and not according to the planning of a company providing services as we often see it nowadays.

In 2007, we renewed our thermoregulation installation by replacing the cold generator by a device at once more powerful and more sober energywise.

In 2008, in order not to suffer from vathouse restraints and to work only depending on the vinification needs, we purchased new tanks. Two new stainless steel truncated fermenters have also replaced our existing tanks in order to improve even more the quality of our Red Sancerre.

In 2013, we invested in a new bottling group, equipped with kits of rinsing and sterilisation of air and water.

We also invested in a third Bucher pneumatic press which greatly helped us in October… The last harvest also gave us the opportunity to get new 600 liter oak barrels (demi- muids) from Stockinger Cooperage and Atelier Centre France .